Chunwang & Environment:

Guard the Ecological Cycle at Its Source

Since its founding, Chunwang has placed social, economic, and environmental responsibilities at the core of its mission. We strive to improve our industry’s environmental impact and benefit society by embedding sustainability across every supply chain stage—from raw material sourcing to finished products—minimizing resource consumption while creating value for all stakeholders.

How Chunwang Delivers on Sustainability

To fulfill this commitment, we implement key initiatives:

- Continuous Improvement: Regularly evaluate and enhance product quality, environmental performance, and sustainability across all processes with company-wide engagement.

- Circular Economy Leadership: Prioritize renewable, reusable, and biodegradable packaging. Champion “resource-reuse” principles for absorbent materials to maximize efficiency.

- Pollution & Carbon Reduction: Minimize air, soil, and water pollution from operations while reducing climate impact throughout product lifecycles.

- Resource Conservation & Waste Management: Systematically reduce energy consumption and waste generation. Responsibly treat all waste from processes and end-of-life products.

- CSR-Integrated Decision Making: Embed corporate social responsibility principles into all business decisions.

- Collaborative Value Chains: Share sustainability goals and best practices with suppliers and partners to jointly advance socio-economic and environmental progress.

Our Journey

Chunwang’s sustainability journey began early: In 2005, we achieved ISO 14001 certification, set concrete CO₂ reduction targets for desiccants, and revamped our Code of Conduct to govern internal and partner operations. Today, amid global sustainability urgency, we’re launching a full line of low-carbon moisture-control and home/personal care products. This is just the start. Moving forward, we’ll innovate efficient, cost-effective, and eco-friendly solutions to advance the circular economy with customers and partners.

Quality & Environment: Our Management Foundation

Our ISO 9001:2015 (Quality) and ISO 14001:2015 (Environmental) certified management systems provide a robust framework to meet stakeholder needs, deliver premium products/services, and continuously reduce operational environmental impact.

Chunwang Calcium Chloride Desiccant

This process transforms soda ash waste liquid into high-value calcium chloride. It creates a waste-to-value closed loop, generating new revenue while co-producing ≈1 ton of reusable sodium chloride per ton of calcium chloride for soda ash recycling. The eco-conscious operation emits primarily water vapor. Resource-efficiently, each ton of desiccant-grade calcium chloride repurposes ≈4 tons of waste liquid and yields ≈1 ton of reusable sodium chloride.

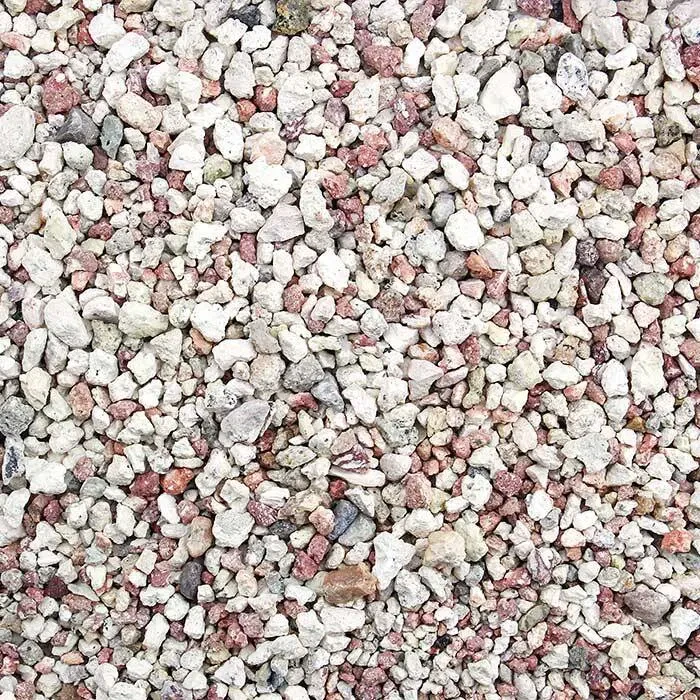

Chunwang Montmorillonite Desiccant

Our montmorillonite (bentonite) is a naturally abundant mineral extracted sustainably under strict environmental protocols, with emphasis on mine rehabilitation. Processing involves physical beneficiation, purification, and low-temperature activation—eliminating harsh chemicals and reducing energy use. The final product: Delivers superior moisture absorption, Safely biodegrades or enriches soil post-use, Leaves near-zero harmful residues

Chunwang Attapulgite Desiccant

Selected attapulgite clay—a unique nano-mineral formed over millennia—is responsibly mined and processed via physical purification, activation, and low-temperature drying. This chemical-free method preserves natural microporous structures while ensuring:

- Exceptional moisture capture

- Complete biodegradation into non-toxic mineral particles

- True “cradle-to-cradle” lifecycle

Chunwang Silica Gel Desiccant

Derived from high-purity sodium silicate (originating in natural quartz sand), our silica gel undergoes controlled acid-washing, rinsing, and thermal activation. The eco-optimized process:

-

Recycles/byproducts

-

Enables regeneration via low-temperature (120°C) drying for reuse

-

Converts end-of-life material into inert, non-toxic silica for construction filler or safe disposal

Green Manufacturing Practices

Pioneering a New Standard in Green Manufacturing: Zero Waste, Low Carbon, and High Efficiency

Industrial Wastewater: Zero Discharge

Our production process focuses on finished product packaging, generating no industrial wastewater or exhaust gases.

%

Reduced Carbon Emissions per Product

Automation has increased production efficiency approximately eightfold over the past decade, reducing carbon emissions per product by about 80%.

%

Noise and Solid Waste Compliance

Machine noise and solid waste are 100% compliant with national emission standards or handled in accordance with relevant regulations.

%

Significantly Reduced Environmental Impact

Extensive use of renewable or biodegradable materials and packaging has improved resource utilization by 75%.

Join Our Corporate Social Responsibility (CSR) Program

Discover how you can contribute by participating in our CSR initiatives. Learn more about Shenzhen Springwang New Material Co., Ltd.’s dedication to sustainability and community development. Partner with us to create a positive impact.