4A Molecular Sieve Desiccant

Product Category: Desiccant

Key Attributes:

- Specifications: 1g – 500g / Customizable sizes available

- Material: 4A Molecular Sieve

- Packaging Material: Mitsubishi Hi-i Paper, Transparent Wax Paper, etc.

- Sealing Type: Three-side sealed

- Printing: Multi-language versions available (Chinese, English, Japanese, etc.)

Product Quotation:

$: Free samples available, detailed pricing upon consultation

Molecular Sieves: An Overview

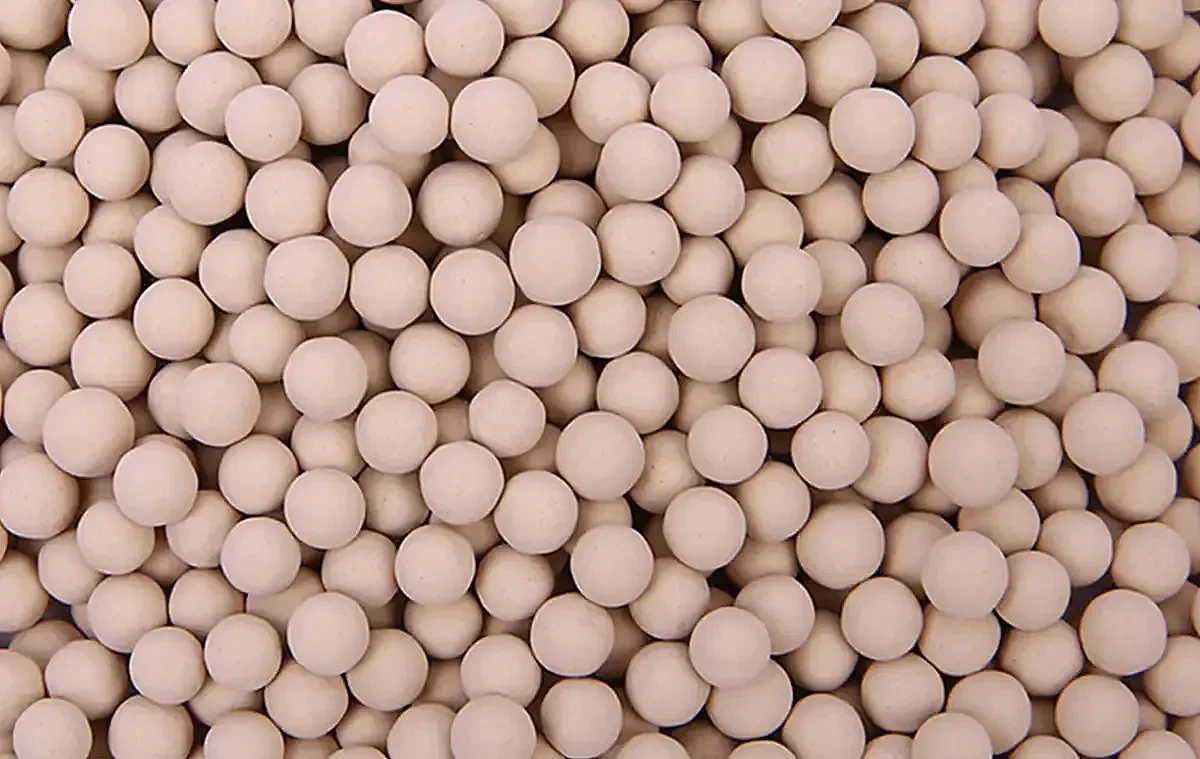

A molecular sieve is a material with a microporous structure, commonly used to adsorb and remove moisture and other gas molecules from the air. The pores of a molecular sieve are extremely uniform in size, enabling it to selectively adsorb molecules based on their dimensions. This property makes it widely applicable in various drying, separation, and purification processes.

Types of Molecular Sieves:

Based on their chemical composition and pore size, molecular sieves are typically categorized as follows:

- 3A Molecular Sieve: With a pore size of approximately 3 Å (0.3 nm), it primarily adsorbs water molecules without adsorbing larger molecules such as nitrogen and oxygen.

- 4A Molecular Sieve: With a pore size of approximately 4 Å (0.4 nm), it adsorbs water molecules, as well as other gases like nitrogen and oxygen.

- 5A Molecular Sieve: With a pore size of approximately 5 Å (0.5 nm), it is suitable for adsorbing slightly larger molecules, such as n-hexane.

- 13X Molecular Sieve: With a pore size of approximately 10 Å (1.0 nm), it is ideal for adsorbing larger gas molecules, including carbon dioxide and hydrogen sulfide.

How Molecular Sieve Desiccants Work?

The internal structure of a molecular sieve contains a vast number of orderly arranged micropores, which create an immense surface area. When gases pass through, molecules are trapped and adsorbed within these pores. Due to its exceptionally high adsorption capacity, the 4A molecular sieve is often used as a desiccant. It remains highly effective even under low humidity or high-temperature conditions.

Key Advantages of Molecular Sieve Desiccants:

The primary advantage of molecular sieve desiccants lies in their deep drying capability. A simple analogy is their ability to create an “extremely dry” environment.

- Standard Desiccants: While they absorb significant moisture, they lose effectiveness in low-humidity conditions. They reach a point where they can no longer adsorb the last traces of ambient moisture. Essentially, they can make an environment dry, but not extremely dry.

- Molecular Sieve Desiccants: Think of them as a highly meticulous super sponge. Not only do they absorb moisture, but they also aggressively seek out and remove the very last traces of humidity. Even in low-moisture environments, they can achieve a state of “deep dryness.”

| Granularity Qualified Rate | >98% |

| Bulk Density | >720g/L |

| Moisture Absorption Rate (T=25°C,RH=80%) | ≥23% |

| Water Content | ≤1.5% |

| PH | 7.0±0.5 |

| Recommend Dosage | 2g/L-2.5g/L |

This desiccant utilizes 4A molecular sieve as its primary material, delivering exceptional drying performance even in low-humidity conditions. While common desiccants like silica gel and calcium chloride can only reduce moisture content to about 0.4 grams per cubic meter, our molecular sieve product dramatically lowers it to below 0.01 grams per cubic meter, proving far more effective when dryness is critical.

The experimental curves reveal that in high-humidity environments, the moisture absorption rate of 4A molecular sieve is notably lower than that of common desiccants. However, its performance becomes exceptional under low-humidity conditions. This clearly demonstrates that molecular sieve desiccants are uniquely suited for low-humidity applications, making them ideal for products that require an extremely dry packaging environment.

Ideal for products that demand an extremely dry environment.

It is commonly used for the static drying of products highly sensitive to moisture, such as camera modules, transformers, PCB circuit boards, electronic components, and pharmaceuticals.

Desiccant Dosage Calculator for Packaging (Click to Enter)

This calculator is designed based on the German Standard DIN 55474.

About Chunwang:

For 27 years, we have been a trusted manufacturer of high-quality desiccants. We produce a wide variety of types, covering all standard specs and packaging, with in-stock items ready for immediate dispatch. We also provide deep customization to fulfill your specific needs. More than just a supplier, we deliver tailored moisture protection solutions to ensure your products stay dry.

Learn More About Chunwang Group >>

Chunwang Advantages:

- Established in 1999, with over 20 years of expertise in R&D and production of desiccants and oxygen absorbers.

- Stock Code: 831880; Stock Abbreviation: Chunwang New Materials.

- Three production bases in Shenzhen, Dongguan,Heyuan, and Anhui, totaling 100,000 m².

- Drafting Unit for the Chinese industry standard BB∕T 0049-2021 (Desiccants for Packaging).

- Drafting Unit for GB/T 41896-2022 (Oxygen Absorbers for Food) and GB/T 41897-2022 (Desiccants for Food).

- Certifications: ISO, BSCI, GMP, High-Tech Enterprise, Specialized & Innovative SME.

- Compliance: RoHS, REACH, TSCA; completed FDA DMF filing.

- National Pharmaceutical Packaging Material Registration No.: B20190000354.

Our company possesses significant technical expertise and industry-leading professional capabilities. Our products incorporate innovative technologies, backed by extensive experience in R&D, stringent quality control, and practical market applications. We are committed to providing customers with efficient, safe, and environmentally sustainable mold and moisture prevention solutions.

View Chunwang VR [Click to View]

Silica Gel Desiccant Overview:

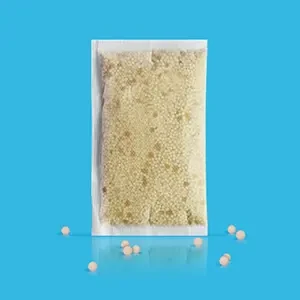

Below are our commonly used molecular sieve desiccant specifications. Standard products ship immediately, and we offer full customization (packaging, print, size, etc.). We have the capability to produce any molecular sieve desiccant configuration found on the market.

Transparent Waxed Paper Molecular Sieve Desiccant

Aiwa Paper Molecular Sieve Desiccant

Related Link: Product Test Reports>>

Related Link: Production Environment>>

Extensive Experience:

With over 20 years of deep industry experience, we have provided leading moisture-proof solutions and products to numerous renowned domestic and international enterprises. We now bring this accumulated expertise directly to your products and production lines, helping you to: Significantly reduce moisture-related damage and guarantee product quality. Safeguard brand reputation to earn lasting market and customer trust.

Our team is here for you (7X24):

We value every single relationship. Big or small, your business is important to us. You can count on our heartfelt enthusiasm and full support whenever you reach out.

Ms. Liu

Gold Medal Sales Rep

Ms. Zhou

Gold Medal Sales Rep

Ms. Zeng

Gold Medal Customer Service

Ms. Lan

Gold Medal Customer Service