Car Lamp Desiccant

Product Category: Desiccant

Key Attributes:

- Type: Specifically designed for car lamps

- Unit Weight: 2g, 5g, 10g, 25g

- Packaging Material: Heat-resistant material

- Sealing: 4-side sealed

- Printing: Standard English printing / Custom printing available

Product Quotation:

$: Free samples available, detailed pricing upon consultation

High Moisture Absorption

Absorption rate up to 220%

with no bleed-back

Long-Lasting Performance

Effective for up to 36 months

in continuous use

Excellent Heat Resistance

Withstands temperatures of

up to 125°C

Safe & Reliable

Locks moisture away as a solid

preventing leaks

Eco-Friendly

Compliant with stringent European Union

environmental standards

Certifications & Compliance

DMF,RoHs,REACH,

SVHC,TSCA,POPs

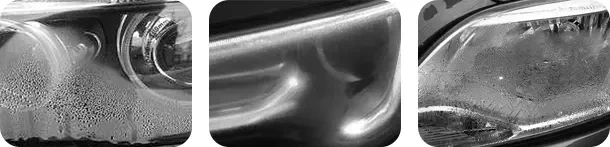

According to major automotive lamp manufacturers, condensation is responsible for at least 70% of all after-sales issues with car lamps. This is a widely recognized and frequent challenge within the industry, resulting from a combination of factors including lamp design, manufacturing processes, usage conditions, and the application of new materials.

(1) Why Is Car Lamp Condensation So Prevalent?

Car lamp condensation, technically known as “lensing,” is fundamentally caused by the interplay of temperature differences and humidity levels inside and outside the lamp assembly. Water vapor in the air within the lamp condenses into droplets upon contact with the cooler inner surface of the lens or housing.

- An Inherent Physical Challenge: Car lamps are not entirely sealed. The heat generated during operation followed by cooling when turned off creates a cycle that promotes condensation. External moisture can enter the assembly through minute vents or gaps necessary for pressure equilibrium (“breathing”).

- Exacerbated by Industry Trends:

1) Electrification & Advanced Features: Modern vehicles, particularly electric ones, incorporate more electronics into lamps, altering heat dissipation patterns. Additionally, the trend towards sleek, complex designs often results in flatter shapes and restricted internal airflow, making it harder for moisture to escape.

2) Material and Cost Constraints: To meet cost targets, some models may utilize materials with less optimal sealing performance or durability. For example, lower-grade breathable membranes may degrade faster, increasing the risk of condensation over the lamp’s lifetime.

(2) The Multi-faceted Impact of Condensation

Condensation is not merely a cosmetic flaw; it leads to significant safety and reliability concerns.

- Compromised Safety: Water droplets on the lens distort the light beam, reducing output intensity and causing undesirable scatter. This diminishes visibility, especially during nighttime or adverse weather conditions, posing a direct safety risk.

- Reduced Component Longevity: Persistent moisture accelerates corrosion of metal components, degrades electrical connections, and can lead to short circuits, potentially causing premature lamp failure.

- Diminished User Experience and Brand Perception: Visible condensation is often perceived by consumers as a sign of poor quality or manufacturing defects, which can negatively impact their confidence in the vehicle brand.

The industry has developed robust and continuously evolving solutions to combat car lamp condensation, primarily through two approaches: “Active Prevention” and “Passive Adsorption”.

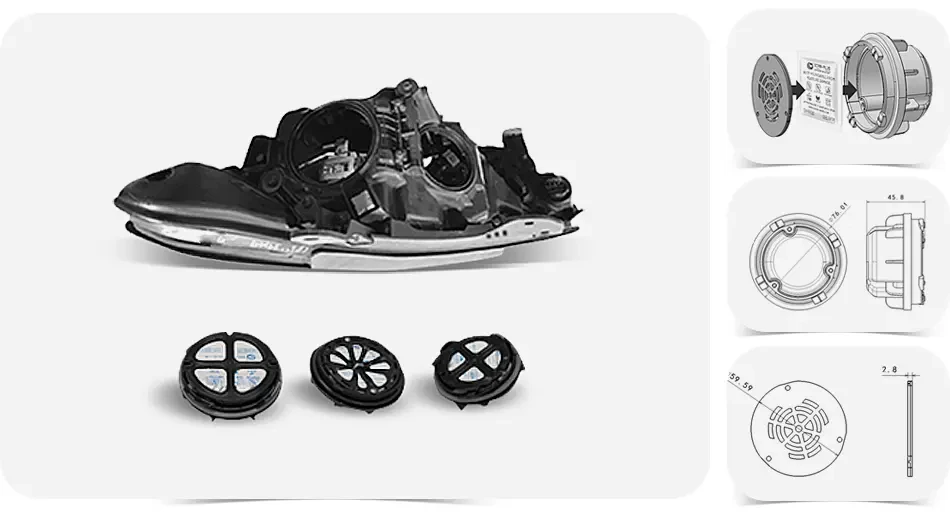

Active Prevention: Car Lamp Venting Membranes

This is the most mainstream solution in original equipment manufacturer (OEM) design. It utilizes a membrane made of expanded Polytetrafluoroethylene (ePTFE). Think of it as a “smart raincoat” for the lamp – it allows water vapor to escape while effectively blocking liquid water and contaminants. A high-performance venting membrane can manage condensation throughout the entire service life of the car lamp.

Passive Adsorption: Car Lamp Desiccant

This is a cost-effective and highly efficient auxiliary method for moisture control. Its main component is typically Magnesium Chloride, known for its strong moisture absorption capability.

- How It Works: Placed in an out-of-the-way corner inside the lamp assembly, the desiccant continuously absorbs moisture from the internal air. This significantly reduces humidity levels, preventing condensation at its source.

- Cost Advantage: For automotive manufacturers, integrating a car lamp desiccant can directly replace or simplify the expensive process of applying anti-fog coatings to the inner lens surface. This change not only streamlines production but also delivers substantial economic benefits. Industry data shows this approach can reduce related manufacturing costs by up to 70% and lower defect rates caused by uneven or failed coating application by over 90%, achieving a win-win for both quality and cost.

- Application Scenarios:

- OEM Design & Manufacturing: Integrated directly as a low-cost, high-reliability alternative to anti-fog coatings.

- Aftermarket Repair: The preferred low-cost repair solution for vehicle owners experiencing minor condensation who wish to avoid the high expense of complete lamp assembly replacement.

- Residual Moisture Control: After a lamp is serviced or replaced, residual moisture may be trapped inside. Placing a desiccant packet quickly absorbs this “existing” moisture.

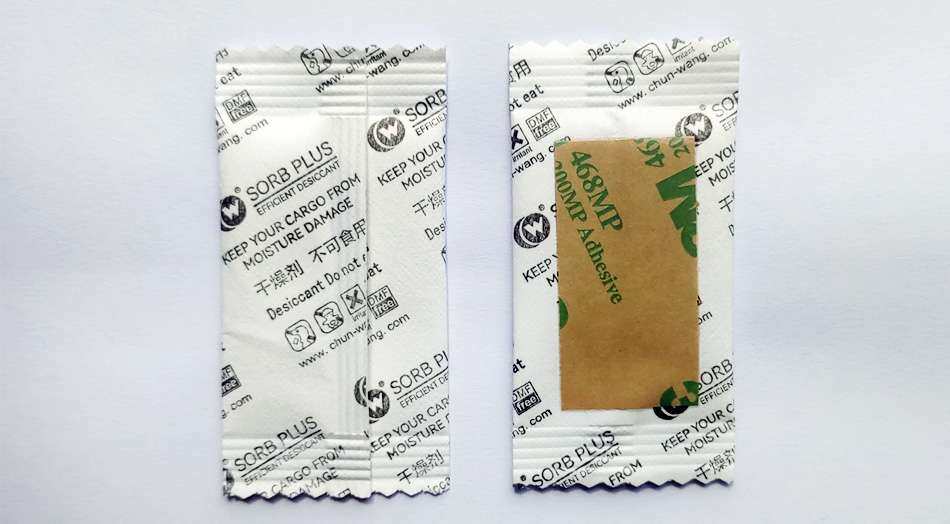

Our Car Lamp Desiccant is made from Magnesium Chloride and polymer adsorbent materials, which effectively capture moisture inside the lamp assembly. After absorption, it gradually hardens into a solid block, preventing any release of trapped moisture.

Before Absorption

During Absorption

After Absorption

The packaging material used for this product is specifically engineered for high-temperature resistance. It has passed rigorous testing, demonstrating its ability to withstand exposure to 125°C for 168 hours without tearing or becoming brittle.

About Chunwang:

With 27 years of specialized experience, we are a desiccant manufacturer producing a comprehensive range of moisture control products. We cover all common specifications and packaging materials, with standard items ready for immediate dispatch. We also support in-depth customization to meet your unique requirements. Beyond manufacturing and sales, we deliver scientific moisture protection solutions, ensuring reliable defense against dampness for your products.

Learn More About Chunwang Group >>

Chunwang Advantages:

- Established in 1999, with over 20 years of expertise in R&D and production of desiccants and oxygen absorbers.

- Stock Code: 831880; Stock Abbreviation: Chunwang New Materials.

- Three production bases in Shenzhen, Dongguan,Heyuan, and Anhui, totaling 100,000 m².

- Drafting Unit for the Chinese industry standard BB∕T 0049-2021 (Desiccants for Packaging).

- Drafting Unit for GB/T 41896-2022 (Oxygen Absorbers for Food) and GB/T 41897-2022 (Desiccants for Food).

- Certifications: ISO, BSCI, GMP, High-Tech Enterprise, Specialized & Innovative SME.

- Compliance: RoHS, REACH, TSCA; completed FDA DMF filing.

- National Pharmaceutical Packaging Material Registration No.: B20190000354.

Our company possesses significant technical expertise and industry-leading professional capabilities. Our products incorporate innovative technologies, backed by extensive experience in R&D, stringent quality control, and practical market applications. We are committed to providing customers with efficient, safe, and environmentally sustainable mold and moisture prevention solutions.

View Chunwang VR [Click to View]

Related Link: Product Test Reports>>

Related Link: Production Environment>>

Our team is here for you (7X24):

We value every single relationship. Big or small, your business is important to us. You can count on our heartfelt enthusiasm and full support whenever you reach out.

Ms. Liu

Gold Medal Sales Rep

Ms. Zhou

Gold Medal Sales Rep

Ms. Zeng

Gold Medal Customer Service

Ms. Lan

Gold Medal Customer Service