Desiccant for Electrochemical Energy Storage

Product Category:Desiccant

Key Attributes:

- Specifications: 120g per stick, customizable

- Format: Individually separated yet connected packets

- Ingredients: Calcium chloride, Magnesium chloride

- Packaging Material: Dumei paper

- Sealing: Sealed on all four edges

- Printing: English / Customizable

Product Quotation:

$: Free samples available, detailed pricing upon consultation

- Critical Challenge

- Root Cause Analysis

- Battery Cell Moisture Protection Solution

- Battery Rack/Cluster Protection Solution

- Energy Storage Container Protection Solution

- Product Selection & Usage Guidelines

Electrochemical (e.g., Lithium-ion, Sodium-ion) energy storage systems are extremely sensitive to humidity. Moisture ingress is one of the core factors leading to performance degradation and safety risks. Energy storage battery cells, packs, and clusters are all high-value products. Significant losses can occur once they are exposed to moisture.

Battery cell

Module (Pack)

Cluster

Core Hazards of Moisture Ingress

- Electrochemical Performance Degradation:

- Side Reactions and Corrosion: Water reacts with lithium salts (e.g., LiPF₆) in the electrolyte to generate corrosive acids (e.g., HF). This corrodes active materials in the cathode and anode, depletes available lithium ions, and leads to irreversible capacity loss.

- Gas Generation and Swelling: Side reactions produce gases, causing increased internal pressure and swelling within the cell/battery pack. In severe cases, this can lead to casing deformation or activation of the vent.

- Increased Internal Resistance: Corrosion products and interface deterioration raise internal resistance, impairing charge/discharge efficiency and power performance while exacerbating heat generation.

- Significantly Increased Safety Risks:

- Internal Short Circuit Risk: A humid environment can cause localized wetting of the separator or corrosion of metal components leading to lithium plating, thereby increasing the probability of short circuits.

- Thermal Runaway Trigger: Moisture-compromised cells exhibit reduced thermal stability during charging, discharging, or under abnormal conditions, lowering the threshold for triggering thermal runaway.

- Physical Corrosion and Insulation Failure (Particularly Critical at the Battery Pack and System Level):

- Electrical Connection Corrosion: Moisture-induced oxidation of high-voltage connectors, such as busbars and terminals, increases contact resistance. This leads to localized overheating, energy loss, and potential connection failure.

- BMS and PCS Component Failure: Moisture exposure to circuit boards and components in control units like the Battery Management System (BMS) and Power Conversion System (PCS) can cause pin corrosion, signal drift, and malfunction or failure of protection features.

- Reduced Insulation Performance: After absorbing moisture, internal insulation materials (e.g., films, epoxy boards) experience a significant drop in insulation resistance. This can lead to high-voltage component leakage to ground, insulation alarms, or the creation of unintended conductive paths.

Why is Moisture Protection Paramount During Storage and Transportation?

- Cells Ship with Residual Charge: Modern battery cells are typically shipped at a 40%-60% State of Charge (SOC) after completing the “formation” (SEI film creation) and “grading” processes to ensure optimal long-term storage life. The combination of this “charged” state and a “humid” environment drastically accelerates the electrochemical degradation process.

- Uncontrollable Environments: Storage, sea freight, and land transportation can span weeks or even months. During this time, the cells are exposed to severe environmental fluctuations—diurnal temperature swings and varying regional climates (e.g., high-humidity salt fog at sea, dry inland air, or seasonal rains)—far exceeding the controlled conditions of a production facility.

- Condensation — The Insidious Threat: During sharp temperature changes (e.g., a cold container arriving at a warm port), the temperature of the battery’s metal casing or internal cold spots may fall below the dew point of the surrounding air. This causes liquid water droplets to form directly on cell surfaces or electrical components, a hazard far more severe than exposure to humid air alone.

- The “Breathing” Effect: Due to temperature and pressure changes during transit, even battery packs with protective enclosures experience internal air expansion and contraction. This pressure differential can actively “draw” external moist air into the system interior.

Which stages of moisture protection can we participate in?

| Product | Production Stage | Storage & Transport Stage | Operational Stage | Value of Our Participation |

| Battery Cell | Not Involved (Strict humidity control in workshop) | Involved (Uncontrollable storage/transport environment) | Not Involved (Humidity managed by energy storage cabinet systems) | Prevents corrosion of charged cells, mitigates capacity fade and safety risks. |

| Battery Pack | Not Involved (Controlled production line environment) | Involved (Uncontrollable storage/transport environment) | Not Involved (Humidity managed by energy storage cabinet systems) | Protects against moisture ingress from “breathing effect”, safeguards BMS & electrical connections, prevents condensation. |

| Battery Rack/Cluster | Not Involved (Controlled production line environment) | Involved (Uncontrollable storage/transport environment) | Not Involved (Humidity managed by energy storage cabinet systems) | Prevents internal condensation & component moisture exposure in complex systems, ensures final delivery quality. |

| Energy Storage Container (Prefab Cabin) | Not Involved (Controlled production line environment) | Involved (Whole-container transport) Involved (Disassembled cluster transport) |

Not Involved (Equipped with independent climate control systems) | Prevents internal condensation & component moisture exposure, ensures final delivery quality. |

Core Challenge: Protecting the charged (40-60% SOC), chemically active entity from moisture-induced irreversible chemical reactions.

1. Warehouse Moisture Protection:

- Scenario: Finished goods warehouses, transfer warehouses (especially those without constant temperature & humidity control).

- Solution: Deploy high moisture-absorption rate hanging desiccant strips within the warehouse, combined with temperature and humidity monitoring. This maintains a stable long-term environmental humidity between 15°C – 30°C and 40% RH – 75% RH. Crucially, condensation must be strictly prevented.

- Recommended Product: Hanging Calcium Chloride or Magnesium Chloride desiccant strips (single-layer packaging).

Hanging Calcium Chloride or Magnesium Chloride desiccant strips

2. Storage & Transportation Phase:

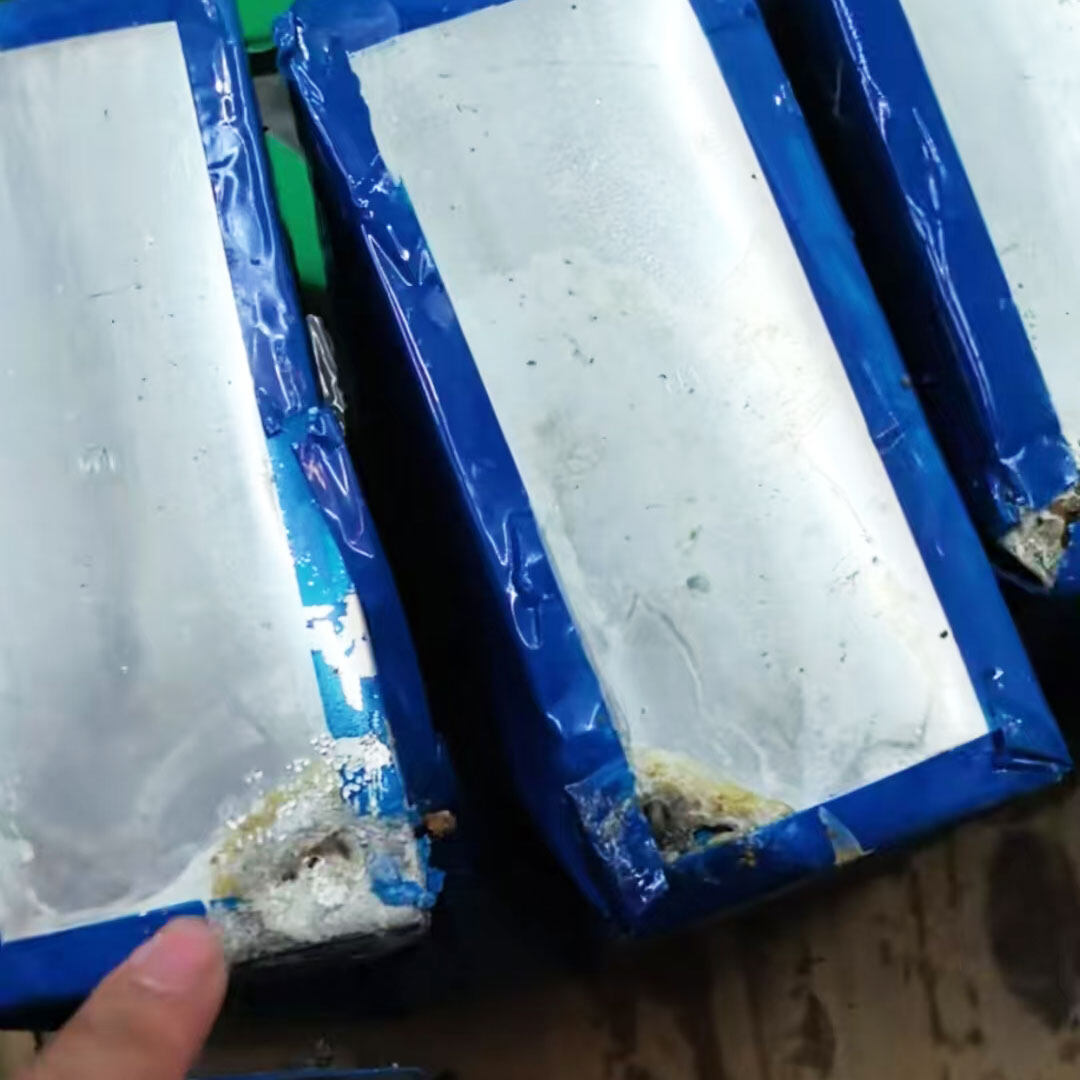

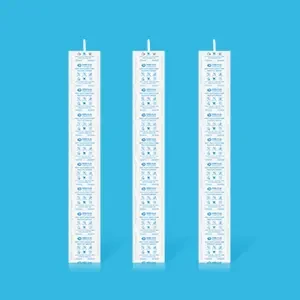

- Inner Packaging Moisture Protection: Apply sufficient adhesive desiccant strips between the battery cell stack and the outer carton. This specialized strip is designed for cell stack packaging. It effectively absorbs any infiltrating trace moisture and residual moisture from the packaging materials themselves, providing enhanced protection against moisture damage to the cells.

Recommended Product: Adhesive, spaced and connected multi-packet desiccants. (For smaller cartons or small-format cell packaging, single packets of physical adsorbents like silica gel or montmorillonite clay desiccants are recommended inside the package.)

Spaced and Connected Multi-Packet Desiccant

Application Illustration of Spaced and Connected Multi-Packet Desiccants

Application Illustration of Single-Packet Silica Gel Desiccants

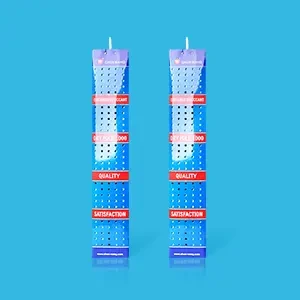

maritime shipping environment, evenly hang “Container-Specific Desiccant Strips” inside the container. Standard dosage: 6-8 strips for a 20-foot container, 10-12 strips for a 40-foot container.

Recommended Products: Vertical-Hanging Container Desiccant Strips (double-layer packaging, hung on the inner sides of the container), Horizontal-Hanging Container Desiccant Strips (double-layer packaging, hung from the top inside the container).

Vertical-Hanging Container Desiccant Strips

Horizontal-Hanging Container Desiccant Strips

Core Challenge: Despite having an enclosure with an IP protection rating, it is crucial to address moisture ingress caused by the “Breathing Effect,” the risk of internal electrical system corrosion, and condensation.

(A common industry misconception to correct: A battery pack’s IP-rated enclosure is designed for dust and liquid water protection, but it cannot prevent the slow infiltration of gaseous water molecules due to pressure differentials. External moisture protection remains essential during storage and transportation.)

1. Warehouse Moisture Protection:

- Scenario: Battery pack finished goods warehouse.

- Solution: In addition to controlling the overall warehouse humidity (refer to Battery Cell Warehouse Protection), for battery packs intended for long-term storage, it is recommended to cover them with a “moisture-proof cover“ or place them inside a “large moisture barrier bag“ to create a “secondary sealed” environment. Place “physical adsorbent desiccants“ (which can contact the battery pack directly with no corrosion risk) and a “humidity indicator card“ inside this barrier.

- Recommended Products: Silica Gel Desiccant, Montmorillonite Clay Desiccant, Humidity Indicator Card.

Silica Gel Desiccant,

Bentonite Desiccant

Humidity Indicator Card

2. Storage and Transportation Phase:

- In-Package Moisture Protection: Inside the battery pack’s shipping crate or sturdy outer packaging, use “adhesive magnesium chloride desiccants“ on the inner walls. Their high moisture absorption capacity and rapid absorption rate effectively buffer against humidity fluctuations caused by significant temperature differentials.

Recommended Product: Adhesive Magnesium Chloride Desiccants

Adhesive Magnesium Chloride Desiccant

Application Effectiveness of Adhesive Magnesium Chloride Desiccants

- Container Shipping: For the high-humidity, high-salt-fog maritime shipping environment, evenly hang “Container Dry Poles“ inside the container and lay “Container Desiccant Blankets“ flat on top of the goods’ wooden crates. Standard dosage: 6-8 rods for a 20-foot container, 10-12 rods for a 40-foot container. The number of blankets can be added as needed based on the shipping route and voyage duration.

Recommended Products: Container Dry Poles (triple-layer packaging with cardboard reinforcement to prevent crushing by wooden crates, hung on the inner sides of the container), Container Desiccant Blankets (double-layer packaging, laid flat on top of the wooden crates).

Container Dry Poles

Container Desiccant Blankets

1. Transport Without Disassembly (Container-Level Shipping):

This method involves factory-level pre-integration, where all core components—such as battery racks, PCS, fire suppression, thermal management, and power distribution systems—are installed, wired, and tested within the factory to form a complete, containerized energy storage unit (prefabricated cabin). This integrated unit is then transported as a whole to the project site.

Core Challenge: As a highly integrated, live electrical system with complex internal spaces and numerous electrical devices, it faces significant risks from the “Breathing Effect” and condensation. Even the accumulation of trace amounts of moisture can pose a serious threat to critical areas like the high-voltage compartment and control cabinets.

Specific Measures:

- Although the energy storage container doors are sealed, to address extreme weather or prolonged transportation, additional waterproof/dustproof covers or sealing tape should typically be applied to areas such as “ventilation openings, external air conditioner grilles, and cable interface panels“ for temporary sealing to prevent moisture ingress. Inside the container, use “hanging connected packets of silica gel or montmorillonite clay desiccant“ (physical adsorbent type, non-corrosive, safe for direct contact).

- Even for container-level shipping, it is still necessary to hang a sufficient quantity of “container-specific desiccant“ inside the shipping container (referring to the sea freight container) to counteract the external high-humidity environment and provide an additional dry buffer zone for the entire prefabricated cabin.

- Upon arrival at the project site, if immediate installation and commissioning are not possible, it is recommended to “maintain the container’s seals and the internal dry environment“ until grid connection and operation.

Recommended Products: Hanging connected packets of silica gel or montmorillonite clay desiccant (for hanging inside the energy storage container), Container Dry Poles (triple-layer packaging with cardboard reinforcement, hung on the inner sides of the shipping container), Container Desiccant Blankets (double-layer packaging, laid flat on top of the goods’ packaging).

Hanging Connected Packets of Silica Gel Desiccant

Hanging Connected Packets of Bentonite Desiccant

Container Dry Poles

Container Desiccant Blankets

2. Transport With Disassembly:

- This shipping method involves disassembling the system down to the “battery pack level“. Transporting these smaller units allows for “tight stacking“, resulting in “lower transportation costs“. Please refer to the previously outlined moisture protection solutions for battery packs during storage and transportation.

| Application Scenario | Primary Risk | Recommended Chunwang Product | Key Points & Dosage Reference |

| Cell / Pack Warehouse | Prolonged exposure to excessive environmental humidity | Hanging Calcium Chloride or Magnesium Chloride Desiccant Strips | Dosage calculated based on warehouse volume, seal integrity, and target humidity. Replace periodically. |

| Inside Cell Packaging Carton | Minimal infiltrating moisture and moisture release from packaging materials | Adhesive Spaced and Connected Multi-Packet Desiccant | Calculate based on internal free air volume. Adhere to the inner walls surrounding the cell stack. |

| Inside Battery Pack Shipping Crate | “Breathing Effect” and condensation | Adhesive Magnesium Chloride Desiccant | Adhere to the crate’s inner walls. Dosage depends on crate volume and estimated transit time. |

| Inside Sea Freight Container | High humidity, salt fog, and sudden temperature changes | Container-Specific Desiccant | 6-8 strips for a 20ft container, 10-12 strips for a 40ft container. Hang evenly. Add desiccant blankets as needed. |

Operational Standards & Safety Management

- Seal First: The effectiveness of all desiccant solutions is predicated on the protected space being as sealed as possible. Performance is significantly reduced in unsealed environments.

- Prevent Condensation: Monitor temperature differentials along the planned shipping route. For cargo expected to undergo drastic temperature swings, increase desiccant dosage and consider using a sealed moisture-proof cover.

- Safe Placement: Desiccant packaging must remain intact to prevent leakage. Avoid any direct contact between desiccant packets and battery cell terminals or other live electrical connectors.

- Inspection Upon Arrival: Upon receipt, inspect the external packaging for integrity and signs of water damage. Check the status of the included Humidity Indicator Card (recommended) as a direct visual indicator of potential moisture exposure.

- System Inspection: For large energy storage containers, conduct a comprehensive pre-commissioning inspection. This must include insulation resistance testing, a visual check of all equipment, and an assessment of internal humidity levels.

- Environmentally Friendly Disposal: Used desiccants must be disposed of in compliance with all applicable local environmental regulations.

Desiccant Dosage Calculator for Packaging (Click to Enter)

This calculator is designed based on the German Standard DIN 55474.

About Chunwang:

We are a desiccant manufacturer with 27 years of professional expertise, capable of producing a wide range of desiccant specifications. Standard products are ready for immediate dispatch, with no waiting required. We also support in-depth customization to meet your specific needs. Beyond simply manufacturing and selling products, we provide scientific moisture-proof solutions to ensure the safety and protection of your goods against humidity.

Learn More About Chunwang Group >>

Chunwang Advantages:

- Established in 1998, with over 20 years of expertise in R&D and production of desiccants and oxygen absorbers.

- Stock Code: 831880; Stock Abbreviation: Chunwang New Materials.

- Three production bases in Shenzhen, Dongguan, and Anhui, totaling 60,000 m².

- Drafting Unit for the Chinese industry standard BB∕T 0049-2021 (Desiccants for Packaging).

- Drafting Unit for GB/T 41896-2022 (Oxygen Absorbers for Food) and GB/T 41897-2022 (Desiccants for Food).

- Certifications: ISO, BSCI, GMP, High-Tech Enterprise, Specialized & Innovative SME.

- Compliance: RoHS, REACH, TSCA; completed FDA DMF filing.

- National Pharmaceutical Packaging Material Registration No.: B20190000354.

Our company possesses significant technical expertise and industry-leading professional capabilities. Our products incorporate innovative technologies, backed by extensive experience in R&D, stringent quality control, and practical market applications. We are committed to providing customers with efficient, safe, and environmentally sustainable mold and moisture prevention solutions.

View Chunwang VR [Click to View]

Extensive Experience:

With over 20 years of deep industry experience, we have provided leading moisture-proof solutions and products to numerous renowned domestic and international enterprises. We now bring this accumulated expertise directly to your products and production lines, helping you to: Significantly reduce moisture-related damage and guarantee product quality. Safeguard brand reputation to earn lasting market and customer trust.

Our team is here for you (7X24):

We value every single relationship. Big or small, your business is important to us. You can count on our heartfelt enthusiasm and full support whenever you reach out.

Ms. Liu

Gold Medal Sales Rep

Ms. Zhou

Gold Medal Sales Rep

Ms. Zeng

Gold Medal Customer Service

Ms. Lan

Gold Medal Customer Service