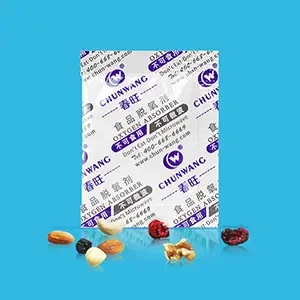

Odor-Removing Food Oxygen Absorber

Product Category: Oxygen Absorber

Key Attributes:

- Type: Odor-Removing

- Feature: Simultaneously absorbs oxygen, VOCs, sulfur compounds, and ammonia substances

- Models: 10#, 20#, 30#, 40#, 50#, 100#, 150#, 200#, 250#, 300#, 500#, 1000#, 1500#

- Sealing: Three-side sealed, Back sealed

- Form: Single piece / Continuous (chain-type / roll-type)

- Printing: Bilingual version (Chinese & English)

Product Quotation:

$: Free samples available, detailed pricing upon consultation

Our Brands

Chunwang (for domestic sales), Ohunter (for international sales)

Main Ingredients

Reduced iron powder, activated carbon, diatomaceous earth, sodium chloride, water.

Nominal Oxygen Absorption Capacity

3 times / >6 times

Reaction Principle

Fe+H2O+O2→Fe(OH)3 | 2Fe(OH)3=Fe2O3 + 3H2O Fe2O3

Optimal Activation Temperature

-5°C to 40°C

Product Packaging Materials

Triple-shield film, triple-shield high-transparency film (Waterproof, Oil-Resistant & Dust-Proof)

The Food Oxygen Absorber, often referred to as a food-grade oxygen scavenger or deoxidizer, is an advanced preservation technology originating from Japan (where it is also known as a “deoxidant”). It is crucial to emphasize that it is not a food additive. Its working principle involves a chemical reaction with the oxygen inside food packaging, consuming the oxygen to create a low-oxygen physical environment.

How It Works: Preserving Freshness at the Source

The core function of the Food Oxygen Absorber is to proactively and precisely remove oxygen from the food packaging environment. Within a specified time, it reduces the residual oxygen concentration inside the packaging to below 0.1% and maintains this near “oxygen-free” state long-term. This reaction process is stable, produces no harmful gases, is safe without side effects, and has thus become an indispensable preservation solution in the food industry.

Product Portfolio: Comprehensive Food Oxygen Absorption Solutions

Leveraging advanced technology, we provide a full range of specialized—not just a single universal type—oxygen absorber products to meet the specific needs of different foods:

- All-Purpose: The Ferrous Universal Food Oxygen Absorber meets the oxygen absorption and preservation requirements for most foods.

- Specialized Types: For different categories such as roasted snacks, betel nuts, pastries, meats, and medicinal herbs, we offer specialized models including the Oxygen Absorber for Roasted Snacks, Moisture-Proof Food Oxygen Absorber, Odor-Removing Food Oxygen Absorber, and Antimicrobial Food Oxygen Absorber.

- Advanced Solutions: For products with special packaging requirements, we provide advanced solutions like the Pressure-Stabilizing Food Oxygen Absorber (prevents package collapse) and the Dual-Absorption Food Oxygen Absorber (absorbs both oxygen and carbon dioxide).

Product Value: All-Round Protection

The Food Oxygen Absorber not only effectively removes oxygen but also provides multiple protective benefits:

- Inhibits Microorganisms: Suppresses the growth and reproduction of mold and aerobic bacteria at the source, preventing food from molding and spoiling.

- Prevents Pest Infestation: Effectively prevents grains, dried fruits, and similar products from developing insects.

- Preserves Color, Aroma, and Taste: Prevents fat rancidity (development of off-flavors) and avoids oxidative discoloration of food (e.g., darkening of nuts, fading of meat), locking in the appealing original color and crisp texture.

- Retains Nutrients: Effectively protects vitamins and natural nutritional components in food from oxidative damage.

Advantages of Using the Food Oxygen Absorber for Preservation

Common preservation methods each have their obvious shortcomings, while the oxygen absorber integrates all the advantages:

❌ Refrigeration: High transportation and storage costs, strong reliance on the supply chain.

❌ Nitrogen Flushing: Leaves 3%-5% residual oxygen in the package, insufficient for perfect preservation; requires significant upfront equipment investment, and the effect is incomplete.

❌ Vacuum Packaging: Requires very high packaging material strength, prone to leakage due to temperature changes or punctures; cannot continuously absorb trace oxygen that infiltrates later.

Only the Food Oxygen Absorber combines convenience, low cost, safety, complete oxygen removal, maintenance of the food’s original color, aroma, and taste, and long-term preservation.

The Odor-Removing Food Oxygen Absorber is a multi-functional, integrated preservation product. Building upon efficient oxygen removal, it features the additional capability of adsorbing odor molecules. It is specifically designed for foods, pharmaceuticals, and premium ingredients that not only undergo oxidative spoilage but also release endogenous odors, providing a “two-pronged” preservation solution.

I. Core Features: Dual Functionality

- Precise Adsorption of Odor Molecules

The specialized adsorbent materials within the product can precisely identify and efficiently adsorb various undesirable odor substances. Its scope of action includes:

Sulfur compounds: Such as hydrogen sulfide, mercaptans, etc., produced during storage in foods containing ingredients like garlic, onion, or leeks, which cause pungent odors.

Ammonia substances: Commonly found during the spoilage of high-protein foods or released by certain aquatic products and traditional Chinese medicines, resulting in an “ammonia odor”.

Certain Volatile Organic Compounds (VOCs): Capable of neutralizing small organic molecules like aldehydes and ketones, mitigating unpleasant odors such as rancidity (from fat oxidation) or stale notes (from fermentation). - Efficient Oxygen Removal for Preservation at the Source

While adsorbing odors, it is first and foremost a highly efficient oxygen absorber. Its core oxygen-removing components rapidly reduce the oxygen concentration inside the package to a very low level (typically <0.1%), fundamentally inhibiting oxidation reactions. This prevents color change, off-flavors, nutrient loss, and microbial growth caused by oxidation in food and pharmaceuticals. - Multi-Effect in One Sachet, Saving Space

It combines deoxygenation and deodorization functions into a single agent, eliminating the need to place two separate functional agents inside the package. This optimizes packaging space, reduces costs, and simplifies production processes.

II. Brief Introduction to the Mechanism of Action

The product achieves its functions through the synergistic effect of physical adsorption and chemical reactions:

- Oxygen Removal Mechanism: Primarily relies on the oxidation reaction of active substances like iron powder to irreversibly consume oxygen.

- Odor Removal Mechanism: Relies on the porous adsorbent materials added internally. Their immense specific surface area and complex pore structure allow them to trap various odor molecules firmly, much like a magnet, thereby achieving the deodorizing effect.

III. Main Application Scenarios

This product is suitable for various scenarios requiring simultaneous oxygen removal and auxiliary odor control, such as:

- Food Sector: Foods containing ingredients like garlic, onion, or leeks; high-protein nutritional foods; dried aquatic products (e.g., dried fish, dried scallops); oil-rich nuts (to reduce oily odors while preventing oxidation).

- Pharmaceutical and Health Product Sector: Certain traditional Chinese medicines, herbal pills, protein powders, etc., that are prone to oxidation and carry characteristic raw material odors.

- Premium Ingredients: High-value dried goods like matsutake mushrooms and dried scallops, to prevent odor transfer and quality deterioration while preserving freshness.

IV. Important Notes

The primary and core function of this product is efficient oxygen removal. The odor removal function is an auxiliary design targeting small amounts of odor molecules released by the product itself. It aims to enhance the overall purity of the product’s flavor profile but is not a substitute for specialized, high-strength deodorants.

Food Oxygen Absorber Dosage Calculator (Click to Access)

This calculator is designed in accordance with GB/T 41896-2022 – National Standard for Food Oxygen Absorbers.

Oxygen Absorber for Roasted Snacks

Features:

- Fast-acting deoxygenation, typically causing packaging to collapse within 30 minutes to 2 hours, creating a vacuum-like state that shortens production line transfer times.

- High oxygen absorption capacity of 140-160 ml of oxygen per gram of absorber.

- Suitable for low water activity foods, ensuring reliable oxygen absorption even in dry environments.

Applications:

Sunflower seeds, peanuts, walnuts, pine nuts, pumpkin seeds, macadamia nuts, and similar roasted snacks.

Important Note:

This product heats up rapidly after opening the package. It must be used within 30 minutes of exposure to air.

Moisture-Proof Food Oxygen Absorber

Features:

- Dual functionality of humidity control and oxygen removal, effectively reducing water activity in high-moisture foods to prevent mold formation.

- Oxygen absorption capacity exceeding 120 ml per gram of absorber.

- Moisture absorption rate ≥30% under 90% RH conditions.

Applications:

Food products with relatively high moisture content, such as: betel nuts.

Important Note:

As a moisture-dependent oxygen absorber, its chemical reaction requires moisture from both the food and packaging environment. It is not suitable for dry foods or dry packaging conditions.

Pressure-Stabilizing Food Oxygen Absorber

Features:

- Releases an equivalent amount of carbon dioxide while absorbing oxygen, preventing food packaging from collapsing.

- Non-ferrous composition, free from metal components, allowing it to pass through metal detectors.

- Safe, environmentally friendly, biodegradable, microwave-safe (unlike iron-based absorbers), and leaves no rust stains.

Applications:

Canned foods, nitrogen-flushed baked goods, sealed museum display cases, etc.

Important Note:

Not suitable for vacuum-packed foods; should not be used with foods that react with carbon dioxide; not recommended for alkaline foods.

Dual-Absorption Food Oxygen Absorber

Features:

- Simultaneously absorbs both oxygen and carbon dioxide, effectively preventing packaging inflation.

- Offers certain moisture absorption capability.

- Provides gentle oxygen removal with relatively mild heat generation and minimal temperature fluctuation during the process.

Applications:

Red dates, coffee beans, and other food products prone to carbon dioxide generation during storage.

Important Note:

As a slow-release oxygen absorber, it is not suitable for food packaging that requires rapid deoxygenation.

Odor-Removing Food Oxygen Absorber

Features:

- Capable of absorbing sulfur compounds and ammonia-based substances.

- Absorbs certain volatile organic compounds to achieve an odor-removing effect.

Applications:

Food and pharmaceutical products that require both oxygen removal and odor elimination.

Important Note:

Its primary function remains oxygen absorption, with odor removal as a supplementary feature. It is suitable for foods that generate small amounts of odor molecules and should not be compared in effectiveness to professional deodorants.

Antimicrobial Food Oxygen Absorber

Features:

- Effective in eliminating Escherichia coli in food products.

- Effective in eliminating Shigella in food products.

- Capable of eliminating other pathogenic microorganisms, achieving a sterilization rate of up to 99.9%.

- Oxygen absorption capacity exceeding 120 ml per gram of absorber.

Applications:

Food products requiring stringent control over total microbial count.

Important Note:

As a slow-release oxygen absorber, it is not suitable for food packaging that requires rapid deoxygenation.

Triple-Shield & Oxygen-Indicating Food Oxygen Absorber:

The specialized types for roasted snacks, moisture-proof, pressure-stabilizing, dual-absorption, odor-removing, and antimicrobial represent functional classifications of our oxygen absorbers. In addition to these, our product line also includes the Triple-Shield Food Oxygen Absorber, manufactured with packaging material that is waterproof, oil-proof, and dust-proof, and the Oxygen-Indicating Food Oxygen Absorber, which features a color-changing indicator line. We offer a comprehensive range of Food Oxygen Absorbers. Please contact our customer service for specific product inquiries and selection assistance.

Food Oxygen Absorber Overview:

Our company offers advanced Food Oxygen Absorbers in a comprehensive range of types, including High-Efficiency Universal, Roasted Snack Specific, Moisture-Proof, Pressure-Stabilizing, Dual-Absorption, Odor-Removing, and Antimicrobial variants. These products effectively eliminate residual oxygen within packaging and maintain an oxygen-free environment for extended periods.They provide multiple protective functions: inhibiting the growth of mold, aerobic bacteria, and grain pests; preventing product mold, spoilage, and insect infestation; avoiding oxidative discoloration of food; preventing lipid oxidation that affects taste; and protecting against the loss of nutrients such as vitamins.

High-Efficiency Ferrous Universal Oxygen Absorber

Yellow Oxygen Absorber – Eye-mark Cut

White Oxygen Absorber – Eye-mark Cut

OHUNTER Export-Series Oxygen Absorber

OHUNTER Export-Series Oil-Resistant Oxygen Absorber

Non-Ferrous Pressure-Stabilizing Oxygen Absorber

Moisture-Proof Oxygen Absorber

Oxygen Absorber for Roasted Snacks

Dual-Absorption Oxygen Absorber

Odor-Removing Food Oxygen Absorber

Antimicrobial Food Oxygen Absorber

Oxygen-Indicating Food Oxygen Absorber

Triple-Shield Oxygen Absorber

Continuous Roll Yellow Oxygen Absorber – Eye-mark Cut

Continuous Roll High-Efficiency Universal Oxygen Absorber

Continuous Roll Triple-Shield Oxygen Absorber

Continuous Roll Oxygen Absorber for Roasted Snacks

Related Link: Product Test Reports>>

Related Link: Production Environment>>

Important Notes:

- Ferrous oxygen absorbers are not microwave-safe, while organic-based absorbers are.

- Oxygen absorbers cannot address spoilage caused by anaerobic bacteria in food products.

- Foods with high oil content or significant moisture require packaging with triple-barrier film (waterproof, oil-proof, dust-proof).

- No oxygen absorber should be immersed directly in food liquids or sauces.

- Pressure-stabilizing oxygen absorbers are unsuitable for alkaline foods or those that react with carbon dioxide.

- All moisture-proof oxygen absorbers uniformly utilize triple-barrier high-transparency film.

- Moisture-proof oxygen absorbers are not recommended for dry food applications.

- Food packaging should employ composite materials with an oxygen transmission rate below 20 ml/m²·24h·25°C, such as KOP/CPP, NY/PE, KNY/PE, KPET/PE, PET/AL/PE. Avoid high oxygen transmission materials like OPP/CPP, PP, or PE film bags.

- After opening the oxygen absorber package, ideally use within 1-2 hours and promptly seal the preserved product. Any unused absorbers should be resealed immediately after removing air from their original packaging to prevent degradation.

- Certain fast-acting oxygen absorber types must be used within 30 minutes after opening the package.

- The optimal operating temperature for food oxygen absorbers generally ranges from -5°C to 40°C; effectiveness decreases below -5°C.

- During operation, food oxygen absorbers generate minimal heat, which is a normal and safe characteristic of the chemical reaction.

About Chunwang:

With 27 years of specialized experience, we are a leading manufacturer of moisture-proof and preservation products, specializing in desiccants and Food Oxygen Absorbers. Our comprehensive product line covers all common specifications and packaging materials, with standard products ready for immediate dispatch—no waiting required. We also offer comprehensive customization options to meet your specific needs. Beyond manufacturing and sales, we provide scientific moisture-proof and preservation solutions to ensure the quality and longevity of your products.

Learn More About Chunwang Group >>

Chunwang Advantages:

- Established in 1999, with over 20 years of expertise in R&D and production of desiccants and oxygen absorbers.

- Stock Code: 831880; Stock Abbreviation: Chunwang New Materials.

- Three production bases in Shenzhen, Dongguan,Heyuan, and Anhui, totaling 100,000 m².

- Drafting Unit for the Chinese industry standard BB∕T 0049-2021 (Desiccants for Packaging).

- Drafting Unit for GB/T 41896-2022 (Oxygen Absorbers for Food) and GB/T 41897-2022 (Desiccants for Food).

- Certifications: ISO, BSCI, GMP, High-Tech Enterprise, Specialized & Innovative SME.

- Compliance: RoHS, REACH, TSCA; completed FDA DMF filing.

- National Pharmaceutical Packaging Material Registration No.: B20190000354.

Our company possesses distinct technological advantages and professional expertise in the industry. We offer innovative products, backed by deep expertise in technology R&D, stringent quality control, and practical market applications. Committed to providing efficient, safe, and environmentally friendly moisture-proof and preservation products, we also deliver tailored solutions to address your specific challenges.

View Chunwang VR [Click to View]

Our Experience:

With extensive expertise in moisture-proof and preservation solutions, we have served diverse industries for over two decades. Throughout our 20+ years of operation, we have consistently provided moisture-proof and preservation products and solutions to numerous renowned domestic and international enterprises. We are committed to leveraging this accumulated professional experience to directly empower your products and production lines—helping you significantly reduce cargo damage, ensure product quality, enhance brand reputation, and earn market trust. Below are some of the notable clients we have collaborated with, both past and present.

Our team is here for you (7X24):

We value every single relationship. Big or small, your business is important to us. You can count on our heartfelt enthusiasm and full support whenever you reach out.

Ms. Liu

Gold Medal Sales Rep

Ms. Zhou

Gold Medal Sales Rep

Ms. Zeng

Gold Medal Customer Service

Ms. Lan

Gold Medal Customer Service