(I) Why Do Import and Export Sea Shipments Get Damp?

Warm air can hold more moisture than cold air. For example, at 40°C, one cubic meter of air can hold up to 51.20 grams of water vapor. But when the temperature drops to 20°C, it can only hold about 17.30 grams. The excess 33.9 grams condenses into water droplets. This explains why dew forms in summer and frost in autumn.

Containers are relatively enclosed spaces. During sea transport, when the temperature inside drops sharply due to external conditions, the excess moisture has no way to escape and condenses into water droplets on the container ceiling and walls. These droplets eventually fall onto the cargo, causing what’s known as “container rain.” Additionally, moisture can be released from wooden floors and the goods themselves. In such damp conditions, goods are prone to mold, deterioration, and corrosion, leading to various forms of damage.

(II) How Do Container Desiccants Prevent Cargo Dampness?

Container desiccants start absorbing moisture from the air inside the container from the moment they are installed. When used in adequate amounts, they help maintain optimal humidity levels inside the container. This ensures that even if temperatures drop suddenly, there won’t be excess moisture in the air to condense. As a result, “container rain” is avoided, and goods remain in a dry and safe environment throughout the shipping process until unloading.

(III) What Are the Essential Requirements for Container Desiccants?

1)High and Fast Moisture Absorption:

Containers are large and not fully sealed. With temperature fluctuations of up to 50–60°C during sea transport, desiccants must absorb moisture quickly and in large quantities to rapidly reduce internal humidity and prevent condensation during sudden temperature drops.

2)Long-Lasting Moisture Absorption:

Since containers are not completely airtight, outside air continuously enters during shipping, bringing additional moisture. Shipping can take 60 days or longer, so desiccants must keep absorbing moisture throughout this period to maintain consistently low humidity levels.

3)Broad Operating Temperature Range:

Extreme shipping conditions may involve temperatures as high as 70–80°C or as low as -10 to -20°C. Desiccants must remain effective across this wide range to properly control humidity inside the container.

4)Safe and Reliable, No Leakage Risk:

If packaging breaks or desiccants spill during transit, liquid leakage could worsen humidity inside the container and increase the risk of cargo damage.

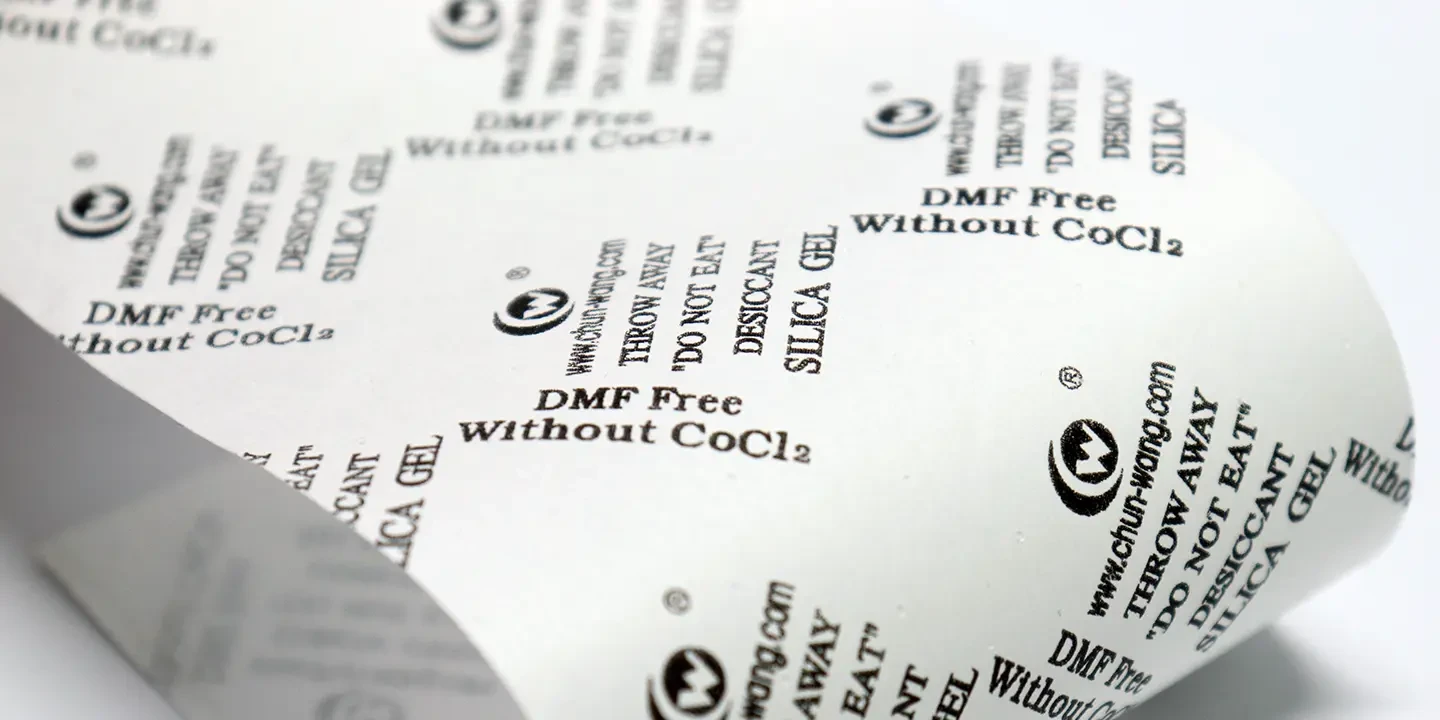

5)Eco-Friendly Compliance:

Environmental regulations in Europe, the U.S., and globally are becoming increasingly strict. As a packaging accessory, desiccants must meet all relevant environmental standards to be suitable for export goods.

(IV) Which Type of Container Desiccant Meets All These Requirements?

Container desiccants made from calcium chloride or magnesium chloride offer high moisture absorption rates, fast action, long-lasting performance, a broad operating temperature range, no leakage, durable packaging, and environmental compliance—making them ideal for all the above requirements. Specifically:

- Under conditions of 25°C and 95% relative humidity, their absorption rate can reach 200%–400%, which is 8–10 times higher than traditional montmorillonite and silica gel desiccants.

- When used in sufficient quantity, they continuously absorb moisture throughout the container until the cargo safely reaches its destination.

- They perform effectively within a temperature range of -5°C to 90°C, making them suitable for extreme shipping conditions. (Other physical adsorption desiccants may release moisture under high temperatures and perform poorly in low temperatures.)

- Once saturated, they turn into a gel or solid block, eliminating leakage risks. Multi-layer packaging also minimizes the chance of damage.

- They comply with ROHS and REACH standards, are free of Dimethylformamide (DMF), and can be disposed of as general waste.

Therefore, only container desiccants specifically designed for maritime shipping, made from raw materials such as calcium chloride or magnesium chloride and featuring sturdy packaging, can effectively meet the demands of cargo transportation during sea voyages.